Top Benefits of Using Telescoping Forklifts in 2025 for Your Business

In 2025, the construction and logistics industries are projected to see significant advancements in equipment technology, with telescoping forklifts emerging as a crucial asset for enhancing operational efficiency and safety. According to a recent report by the Material Handling Industry of America, the use of telescoping forklifts is expected to increase by over 25% as businesses seek versatile solutions that can adapt to various lifting challenges. This uptick is largely driven by the growing demand for equipment that can provide extended reach and lifting capabilities without compromising safety or stability.

Industry expert Dr. Samantha Green, a leading analyst at the Construction Equipment Institute, emphasizes the importance of adopting innovative lifting technologies: "Telescoping forklifts are not just tools; they are strategic investments that can dramatically improve workplace productivity while ensuring safety standards are met." Companies that incorporate telescoping forklifts into their operations will not only benefit from their ability to access hard-to-reach areas but will also enhance their overall efficacy in completing complex projects. As businesses navigate the evolving landscape of construction and materials handling, the advantages of telescoping forklifts will play a pivotal role in driving success and maintaining competitiveness in the market.

Key Advantages of Telescoping Forklifts for Businesses in 2025

Telescoping forklifts are becoming essential tools for businesses in various sectors in 2025. Their unique design provides operators with enhanced versatility and efficiency, allowing them to reach heights and distances that traditional forklifts cannot. According to a recent industry report, the demand for telescoping forklifts is projected to grow by 15% over the next five years, highlighting their increasing importance in material handling and logistics operations. These machines are particularly valuable for construction and warehousing, where reach and maneuverability can significantly impact productivity.

One significant advantage of telescoping forklifts is their ability to operate in tight spaces while still providing extensive lifting capabilities. This makes them ideal for indoor applications as well as outdoor tasks that require navigating challenging terrains. Furthermore, many models now feature advanced safety systems and user-friendly controls, which improve operator confidence and reduce the risk of on-site accidents. As a result of these innovations, businesses can expect to see a reduction in labor costs and an increase in safety compliance, which is crucial in today's regulatory environment.

Tips: When considering the integration of telescoping forklifts into your operations, ensure that your staff is adequately trained on their specific functionalities and safety measures. Additionally, regular maintenance checks can prolong the lifespan of these machines, ultimately leading to greater returns on investment. Lastly, assess your specific operational needs to choose the right model that best fits your business requirements, ensuring optimal performance and productivity.

Enhanced Versatility: Adapting to Various Tasks with Telescoping Forklifts

Telescoping forklifts are increasingly becoming essential tools in modern warehouses and construction sites due to their enhanced versatility. Unlike traditional forklifts, telescoping forklifts feature extendable booms that allow operators to reach materials at greater heights and distances, making them ideal for a wide range of tasks. According to a market analysis by Grand View Research, the global telescopic forklift market is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2020 to 2027, emphasizing the rising demand for versatile handling equipment in various industries. This flexibility enables businesses to transition smoothly between diverse operations, whether lifting heavy loads, stacking materials, or performing outdoor tasks in challenging terrains.

Furthermore, the adaptability of telescoping forklifts allows companies to optimize their workforce and equipment usage. A report by IBISWorld highlights that the construction industry alone accounted for over 50% of the demand for telescopic handlers in the last few years, proving their significance in outdoor projects where bulky materials are often relocated. These machines not only save time but also reduce the need for multiple types of equipment on site, thus translating into cost savings and increased efficiency. The ability to adjust the boom's reach and height empowers operators to handle unique lifts that standard forklifts cannot manage, ensuring that businesses are well-prepared to tackle diverse tasks as they arise.

Top Benefits of Using Telescoping Forklifts in 2025

In 2025, telescoping forklifts offer enhanced versatility for businesses by adapting to various tasks in material handling. The following chart illustrates the key benefits experienced by businesses utilizing these machines, showcasing the percentage of users who reported improvements in different operational areas.

Improved Efficiency: How Telescoping Forklifts Boost Productivity in 2025

In 2025, the efficiency of warehouse operations and construction sites has reached new heights, largely due to the adoption of telescoping forklifts. These versatile machines offer significant advantages in boosting productivity by enhancing material handling capabilities. With their extendable booms, telescoping forklifts can reach elevated heights and navigate tight spaces that traditional forklifts struggle with. This flexibility allows workers to move materials swiftly and safely, reducing downtime and optimizing workflow.

Moreover, the ergonomics of telescoping forklifts contribute to improved employee performance. Operators benefit from better visibility and reduced physical strain while maneuvering these machines, allowing them to work longer with fewer fatigue-related errors. The integration of advanced technologies, such as automated controls and load sensing systems, further enhances operational efficiency. Businesses leveraging these advancements find that they can take on more projects simultaneously, leading to increased output and overall profitability as they adapt to the demands of a competitive marketplace.

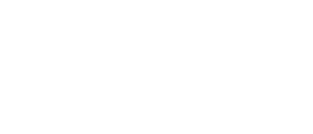

Safety Features: Ensuring Worker Protection with Modern Telescoping Forklifts

Modern telescoping forklifts are becoming essential tools in various industries for their versatility and safety features. The emphasis on worker protection has never been more critical, particularly with the increase in workplace injuries related to material handling. According to a recent report by the National Institute for Occupational Safety and Health (NIOSH), workplace accidents in the material handling sector account for approximately 25% of all work-related injuries. Thus, investing in advanced telescoping forklifts in 2025 can significantly enhance safety measures at your business.

These modern forklifts often come equipped with advanced safety features such as stability monitoring systems, enhanced visibility cabs, and collision avoidance technology. The integration of these features leads to a reduction in accidents and promotes a safer working environment. A study by the Occupational Safety and Health Administration (OSHA) reveals that companies that adopt advanced safety technologies have seen up to a 30% decrease in workplace incidents.

**Tip:** Regularly train your employees on the safety features of telescoping forklifts and encourage them to utilize these tools properly to minimize risk.

Additionally, employing telescoping forklifts that are fitted with load monitoring systems can prevent overloading, a common cause of forklift accidents. This technology ensures that workers can safely handle heavier loads without risking their safety or jeopardizing the integrity of the equipment.

**Tip:** Conduct frequent safety audits to ensure that all telescoping forklifts are functioning well and that safety protocols are being followed diligently. This proactive approach can foster a culture of safety and empower employees to perform their jobs without unnecessary risks.

Cost-Effectiveness: The Financial Benefits of Using Telescoping Forklifts

In 2025, the use of telescoping forklifts is anticipated to bring significant cost-effectiveness to businesses across various industries. One of the primary financial benefits lies in their ability to increase operational efficiency. With their extended reach and enhanced lifting capabilities, telescoping forklifts can streamline material handling processes, allowing businesses to complete tasks faster and with fewer labor hours. This time-saving feature translates into reduced labor costs, allowing companies to allocate resources more effectively.

Moreover, telescoping forklifts are designed for optimal fuel efficiency, which directly impacts the bottom line. As businesses seek to maintain sustainability while managing expenses, the low fuel consumption of these machines becomes extremely appealing. By minimizing fuel costs, companies can experience significant savings over time. Additionally, the versatility of telescoping forklifts means that they can handle a wide range of tasks and materials, diminishing the need for multiple specialized vehicles. This consolidation not only cuts down on acquisition costs but also reduces maintenance expenses associated with managing a diverse fleet. Overall, the financial advantages of incorporating telescoping forklifts into operations make them an essential investment for forward-thinking businesses in 2025.

Related Posts

-

How to Choose the Right Crane Truck Rental for Your Project Needs

-

10 Best Types of Construction Cranes for Efficient Project Management

-

What Is Crane Rentals? Understanding Costs, Types, and Benefits of Renting Cranes

-

10 Essential Tips for Operating Truck Cranes Safely and Efficiently

-

Discover the Best 2025 Telehandler Lift Models for Efficient Heavy Lifting

-

Top 10 Best Tadano Cranes for Heavy Lifting in 2023