Best Portable Tower Cranes for Easy Construction Operations in 2023

In the ever-evolving landscape of construction operations, the demand for efficiency and versatility has led to the increased popularity of portable tower cranes. These innovative machines not only enhance productivity on-site but also offer unparalleled mobility, making them an ideal choice for various construction projects. According to industry expert John Carter, a renowned engineer with decades of experience in the construction equipment sector, "The advantage of a portable tower crane lies in its adaptability and efficiency, allowing construction teams to tackle projects with ease and precision."

As we examine the best portable tower cranes available in 2023, it is essential to consider the unique features that set these cranes apart from traditional options. The ability to transport these cranes conveniently between locations provides significant advantages, particularly for companies that engage in diverse construction activities across multiple sites. Furthermore, their streamlined design allows for quick assembly and disassembly, ensuring that projects can commence and complete on schedule.

With the advent of new technologies and design enhancements, modern portable tower cranes are more efficient than ever, making them a vital asset in today’s competitive construction environment. This exploration will delve into the leading options within the portable tower crane market, showcasing how these cranes are revolutionizing construction operations and driving productivity forward.

Overview of Portable Tower Cranes in Construction

Portable tower cranes have become an essential tool in modern construction due to their efficiency and versatility. These cranes provide a compact and mobile solution for lifting heavy materials and equipment across various job sites, making them particularly valuable for smaller projects or locations with limited space. Their ability to reach significant heights while maintaining a relatively small footprint allows contractors to optimize their operations and improve productivity.

In addition to their space-saving advantages, portable tower cranes are designed for ease of assembly and disassembly, making them ideal for temporary construction sites. They can be quickly set up and relocated, minimizing downtime and labor costs. Furthermore, advancements in technology have led to enhanced safety features and automated functions that streamline the lifting process, ensuring a safer working environment for construction teams. As the demand for efficient construction methods continues to grow, portable tower cranes stand out as a practical solution, facilitating smooth and effective operations across various sectors of the industry.

Key Features to Look for in Portable Tower Cranes

When selecting a portable tower crane for construction operations, it's essential to consider several key features to ensure efficiency and safety. First and foremost, pay attention to the crane's lifting capacity. Portable tower cranes can vary significantly in terms of maximum load, which directly impacts the types of tasks they can perform. Ensure the crane’s capacity aligns with the demands of your project, allowing for a margin to avoid overloading.

Another critical feature to evaluate is the crane's height and reach. The ability to adjust the height and extend the boom is vital for multi-story construction jobs. Look for cranes with a flexible design that can adapt to different site conditions. Additionally, mobility is a crucial consideration. A crane that is easy to transport and set up will reduce downtime and improve overall workflow on-site.

Tips: Always check the crane's stability features, such as outriggers and counterweights, to enhance safety during operations. Additionally, consider a model that offers intuitive controls for operators, which can significantly decrease the learning curve and increase productivity. Regular maintenance checks are also essential to ensure that the crane remains in optimal working condition throughout the project duration.

Best Portable Tower Cranes for Easy Construction Operations in 2023

Top Brands and Models of Portable Tower Cranes for 2023

In 2023, the demand for portable tower cranes has surged due to the increasing need for flexible construction solutions across various industries. As outlined in a recent industry report by the Global Construction Industry Association, the portable crane market is projected to grow by 8% annually, driven by advancements in technology and a greater emphasis on efficiency in construction operations. Various models have been released that cater to the needs of both small-scale and large-scale projects, providing enhanced maneuverability and ease of use.

When selecting a portable tower crane, key factors such as lifting capacity, maximum height, and overall weight play a significant role in determining suitability for specific construction tasks. Leading industry analysts highlight that cranes with modular designs are particularly favored for their adaptability and ease of transport, essential for projects with varying site conditions. Moreover, innovations in materials and engineering have led to cranes that are not only robust but also lightweight, allowing for greater accessibility and reduced operational costs. As construction projects continue to evolve, having the right equipment becomes critical to maintaining productivity and ensuring safety on job sites.

Best Portable Tower Cranes for Easy Construction Operations in 2023

| Model | Maximum Load (tons) | Height (meters) | Operating Radius (meters) | Weight (kg) |

|---|---|---|---|---|

| Model A | 4 | 30 | 25 | 3000 |

| Model B | 5 | 35 | 28 | 3500 |

| Model C | 6 | 40 | 30 | 4000 |

| Model D | 7 | 45 | 32 | 4500 |

| Model E | 8 | 50 | 35 | 5000 |

Safety Considerations When Operating Portable Tower Cranes

When operating portable tower cranes, safety should always be the top priority. These cranes, designed for easy transport and rapid deployment, can provide significant advantages on construction sites. However, their operation involves certain risks that require careful consideration. Operators should ensure that all personnel are trained and familiar with crane functions, and that a comprehensive safety checklist is followed before commencing any work.

Regular inspections of the equipment are crucial. Operators should examine rigging components, check for wear and tear, and ensure that all safety devices are functioning properly. Additionally, it is important to secure the crane on stable ground to prevent tipping, particularly in windy conditions or on uneven surfaces. Ensuring that the load limits are understood and adhered to can prevent accidents and equipment failures.

Tips for maintaining a safe work environment include:

- Establish a Safety Zone: Mark a designated area around the crane to keep unauthorized personnel at a safe distance during operations.

- Communicate Clearly: Utilize hand signals or radios to maintain clear communication among the team, especially in noisy environments. This helps avoid miscommunication that could lead to dangerous situations.

- Monitor Weather Conditions: Always consider environmental factors before operating the crane. Wind speeds and precipitation can significantly impact the crane's stability and operational safety.

Comparative Analysis of Portable vs. Traditional Tower Cranes

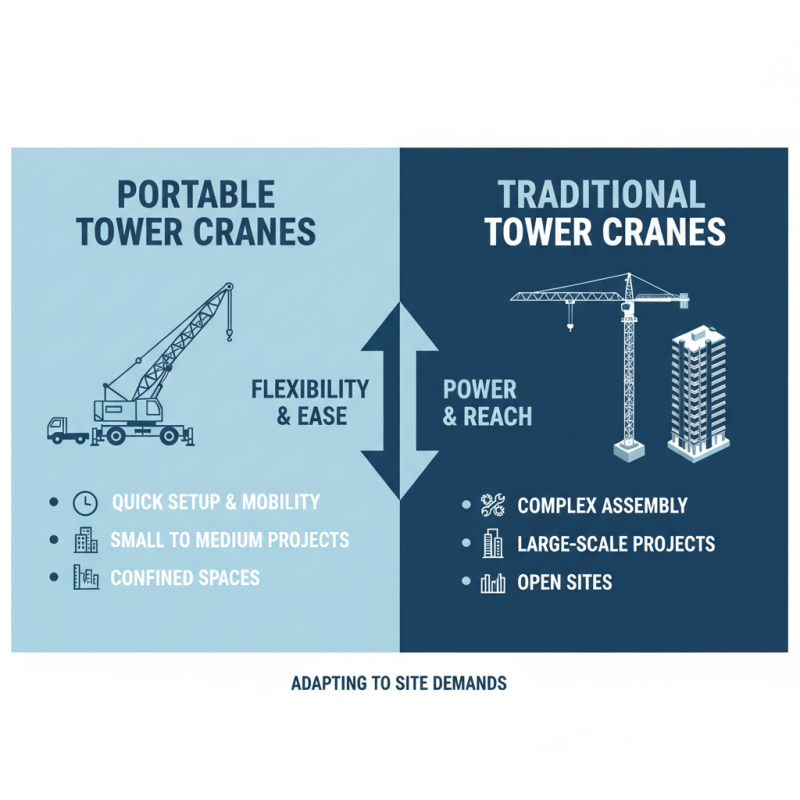

When comparing portable and traditional tower cranes, it is essential to consider the specific demands of construction sites. Portable tower cranes are designed for flexibility and ease of use, allowing for quick setup and mobility. They can be transported easily between job sites, making them a cost-effective choice for small to medium-sized projects. Their lightweight structure and compact design enable them to operate in confined spaces, which is becoming increasingly important as urban construction projects often face spatial constraints.

On the other hand, traditional tower cranes are typically larger and more robust, offering greater lifting capacity and reach. They are better suited for larger construction projects where heavy lifting is a frequent requirement. Their stationary nature means they can support significant loads over extended periods, making them ideal for skyscraper constructions or large commercial facilities. However, their installation is more complex and time-consuming, which can lead to increased labor costs and downtime.

Ultimately, the choice between portable and traditional tower cranes depends on the specific project requirements, including site conditions, budget, and lifting needs. While portable cranes provide unparalleled flexibility, traditional cranes excel in heavy-duty applications. Each type has its unique advantages that cater to different aspects of construction operations.

Related Posts

-

10 Essential Tips for Operating Truck Cranes Safely and Efficiently

-

2025 Top 10 Self Erecting Crane Models Revolutionizing Construction Efficiency

-

Discover the Best 2025 Telehandler Lift Models for Efficient Heavy Lifting

-

2025 Guide: How to Choose the Best Crane Truck Rental for Your Project

-

2025 Top 5 City Crane Innovations Transforming Urban Construction

-

Top Benefits of Using Telescoping Forklifts in 2025 for Your Business