10 Best Types of Construction Cranes for Efficient Project Management

In the ever-evolving field of construction, the efficiency and effectiveness of project management are heavily influenced by the selection of suitable equipment. Among these, construction cranes play a pivotal role in ensuring that projects are completed on time and within budget. According to Dr. Emily Harper, a renowned expert in construction management, "The right construction crane can significantly enhance site productivity and safety, leading to a smoother workflow and better project outcomes." Her insight underscores the importance of understanding different types of cranes and their specific applications.

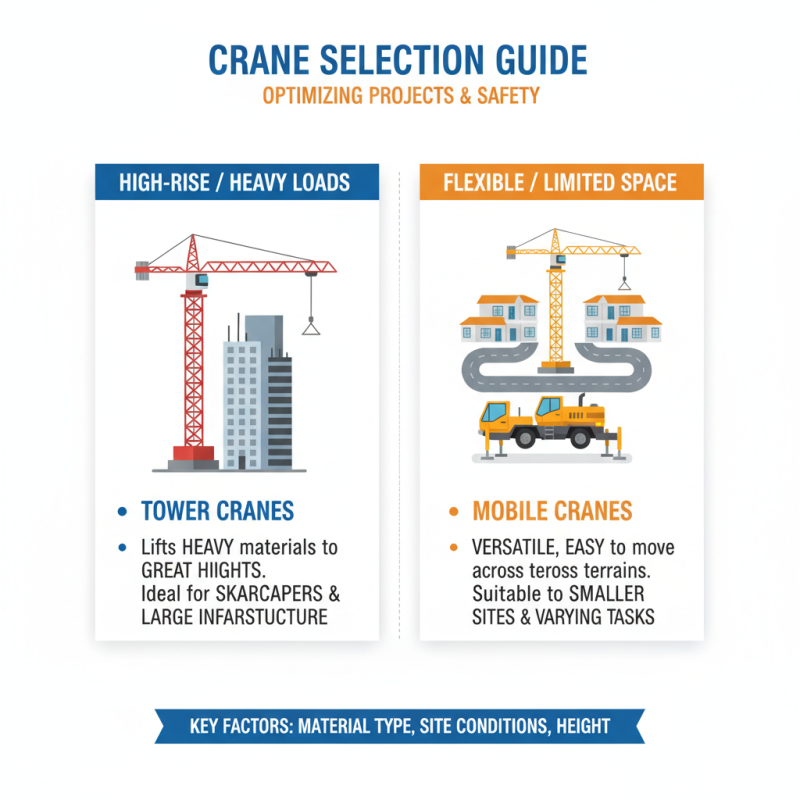

Construction cranes come in various forms, each designed to handle unique challenges on the job site. From the towering tower cranes that dominate urban skylines to the versatile mobile cranes that provide flexibility across diverse terrains, each type offers distinct advantages for managers seeking to optimize their construction processes. By carefully selecting the appropriate crane, project managers can not only streamline operations but also mitigate risks, enhance worker safety, and foster better coordination among teams. As such, understanding the best types of construction cranes available is essential for any manager looking to push the boundaries of project management efficiency.

Types of Cranes: An Overview of Their Role in Construction Projects

Cranes play a pivotal role in construction projects, serving as essential machinery that enhances the efficiency and safety of material handling. There are various types of cranes, each designed for specific tasks, from lifting heavy materials to maneuvering them into place. Whether it's tower cranes utilized for high-rise construction or mobile cranes suited for diverse job sites, understanding their unique functions allows project managers to select the right equipment for their needs.

When selecting a crane for a construction project, consider the project's specific requirements, including the height and weight of materials to be lifted. Tips to optimize crane usage include ensuring adequate space for operation, conducting regular maintenance checks to prevent malfunctions, and training operators on the proper handling and safety protocols. Additionally, it's vital to analyze the site conditions, such as ground stability and accessibility, to prevent potential hazards during lifting operations.

Furthermore, always maintain clear communication between the crane operator and ground team. Implementing a reliable signaling system can significantly reduce the risk of accidents and ensure a seamless workflow on the site. Proper planning and collaboration can lead to enhanced productivity, making the most of the crane’s capabilities while navigating the complexities of construction projects.

10 Best Types of Construction Cranes for Efficient Project Management

| Type of Crane | Capacity (Tons) | Height of Lift (ft) | Typical Use Case | Mobility |

|---|---|---|---|---|

| Tower Crane | 10-100 | 100+ | High-rise buildings | Stationary |

| Mobile Crane | 5-100 | 30+ | Construction sites | Mobile |

| Rough Terrain Crane | 15-70 | 40+ | Off-road projects | Mobile |

| Crawler Crane | 50-200 | 100+ | Heavy lifting | Mobile |

| Truck-mounted Crane | 10-60 | 50+ | Urban projects | Mobile |

| Floating Crane | 50-1000 | Varies | Maritime construction | Stationary |

| Luffing Jib Crane | 15-50 | 85+ | Narrow sites | Stationary |

| Self-erecting Crane | 10-20 | 60+ | Residential buildings | Stationary |

| Articulating Crane | 5-30 | 20+ | Maintenance tasks | Mobile |

| Tower Lifting Crane | 20-40 | 70+ | Power line construction | Stationary |

Essential Features of Each Crane Type for Project Management Efficiency

When managing construction projects, selecting the right type of crane can significantly influence efficiency and workflow. Various crane types come with essential features that cater to diverse project needs. For instance, tower cranes are perfect for tall structures, thanks to their height and lifting capacity, while mobile cranes offer flexibility and ease of movement on-site. For projects requiring precise placement, the use of a lattice boom crane can enhance control, making them suitable for construction sites that demand accuracy.

Tips for choosing the right crane include assessing the project size and height requirements. For larger sites, consider utilizing crawler cranes, which provide stability and traction. Moreover, evaluate the crane's reach and load capacity to ensure it meets the specific demands of the project. Always prioritize crane features that optimize safety, such as load moment indicators and overload protection systems, which are critical for preventing accidents and ensuring compliance with safety standards in the construction industry.

Another important consideration is the terrain of the construction site. If working on uneven ground, a rough terrain crane may be necessary to navigate challenges effectively. Additionally, communication between operators and project managers is vital to ensure seamless operation and coordination. By thoroughly understanding the essential features of each crane type, project managers can enhance overall productivity and minimize downtime on site.

Comparative Analysis of Crane Types: Advantages and Limitations

When choosing the right type of crane for construction projects, understanding the advantages and limitations of each type is critical for effective project management. Tower cranes, for instance, are highly efficient for tall buildings due to their height and lifting capacity. They can lift heavy materials to significant heights, making them ideal for skyscrapers. However, their setup requires extensive planning and can take considerable time, which may delay the project if not scheduled carefully.

On the other hand, mobile cranes offer versatility and quick relocation, which is beneficial for projects that require mobility across different sites. Their limitation lies in stability and load capacity when compared to tower cranes, particularly for heavy lifting. This choice often necessitates a balance between speed and safety considerations.

Tips: Always conduct a thorough analysis of the project's requirements before selecting a crane type and consider factors like site conditions, load weight, and height. Additionally, involve crane operators early in the planning phase to leverage their expertise, ensuring optimal crane selection and placement for efficiency and safety during operations.

Selecting the Right Crane for Specific Construction Needs and Conditions

Selecting the right crane for specific construction needs and conditions is crucial for the efficiency and safety of any construction project. First, it is essential to assess the nature of the project, including the type of materials to be moved, the site conditions, and any height restrictions. For instance, tower cranes are excellent for high-rise buildings due to their ability to lift heavy loads to great heights, while mobile cranes offer flexibility and ease of movement across various terrains, making them suitable for smaller sites or projects with limited space.

Additionally, environmental factors such as wind conditions, ground stability, and proximity to existing structures must be taken into account. For example, in urban areas where space is tight, a compact crane can maneuver easily without interfering with ongoing operations. Furthermore, the lifting capacity and reach of the crane must align with the specific construction tasks, ensuring that the selected equipment can handle the demands of the job without compromising safety. Proper crane selection ultimately leads to improved project management, reducing downtime and enhancing productivity on construction sites.

Future Trends in Crane Technology and Their Impact on Construction Management

As crane technology continues to evolve, the future of construction management is increasingly intertwined with advancements in automation, data analytics, and sustainable practices. The integration of smart technology into cranes allows for real-time monitoring of operations, enhancing safety and efficiency on job sites. Systems equipped with sensors can collect data on load management and environmental conditions, providing project managers with valuable insights to optimize crane performance and streamline workflows. This shift towards data-driven decision-making empowers construction teams to respond more swiftly to challenges while minimizing downtime.

Moreover, the growing emphasis on sustainability in construction is prompting innovations in crane design and operation. Electric and hybrid cranes are becoming more prevalent, reducing emissions and energy consumption on sites. These eco-friendly options not only contribute to a miniature carbon footprint but also align with regulatory pressures and market demands for greener practices. As the construction industry embraces these trends, project managers will need to stay informed about technological advancements, ensuring they can effectively leverage new equipment and methodologies to enhance project outcomes and drive efficiency in construction management.

10 Best Types of Construction Cranes for Efficient Project Management

Related Posts

-

2025 Guide: How to Choose the Best Crane Truck Rental for Your Project

-

Discover the Best 2025 Telehandler Lift Models for Efficient Heavy Lifting

-

How to Choose the Right Crane Truck Rental for Your Project Needs

-

2025 Top 10 Self Erecting Crane Models Revolutionizing Construction Efficiency

-

Top 10 Best Tadano Cranes for Heavy Lifting in 2023

-

Top 5 Boom Trucks That Will Transform Your Construction Projects