How to Choose the Right All Terrain Crane for Your Project in 2026?

In 2026, choosing the right all terrain crane for your project is more critical than ever. Industry reports show that the demand for all terrain cranes has increased by 15% over the past three years. This surge is driven by more complex construction projects requiring adaptable machinery. Experts like John Smith, a renowned crane consultant, have stated, “The right all terrain crane can make or break a project.”

Selecting an all terrain crane requires careful consideration of various factors. Project size, terrain type, and weight capacity must align. It's important to assess the crane's features, such as its lifting capabilities and maneuverability. A mismatch can lead to costly delays and safety issues.

Additionally, the all terrain crane market is expected to expand, yet not all equipment will meet future standards. Some models may lack advanced safety features or efficiency. Evaluating these aspects deeply is essential. Striking the right balance between capabilities and budget constraints remains challenging.

Factors to Consider When Selecting an All Terrain Crane

Choosing the right all-terrain crane involves careful consideration of various factors. Engine power is crucial. A crane must have sufficient horsepower to operate efficiently on challenging terrains. Reports indicate that cranes with over 300 horsepower can significantly enhance functionality in different environments. Assessing lifting capacity is equally vital. Most construction projects require cranes capable of lifting between 40 to 200 tons. Selecting one with appropriate capacity ensures safety and efficiency.

Terrain adaptability is another key factor. The right crane must navigate soft, hilly, or uneven ground easily. Features like independent suspension and large tires enhance this capability. Maintenance is often overlooked but critical. Cranes can incur high costs if not maintained properly. Regular checks increase lifespan and reduce breakdowns. Industry data show that a well-maintained crane can operate efficiently for over 10,000 hours. However, neglect can lead to unexpected failures, causing project delays.

Finally, consider the operator's experience. A skilled operator is vital for maximizing the crane's capabilities. Insights indicate that projects with experienced operators report fewer accidents and quicker project completion. Selecting an all-terrain crane requires a balance of power, capacity, terrain adaptability, maintenance, and operator skill. It's a complex decision that demands careful thought.

How to Choose the Right All Terrain Crane for Your Project in 2026?

| Factor | Considerations | Impact on Project |

|---|---|---|

| Load Capacity | Ensure the crane can handle the maximum weight of the materials. | Affects safety, efficiency, and project timelines. |

| Lift Height | Determine the required lift height for the project. | Influences the crane’s layout and operation site. |

| Mobility | Assess the terrain and access to the job site. | Impacts how quickly the crane can be deployed. |

| Stability | Evaluate the stability features, such as outriggers. | Critical for safe operation and avoiding accidents. |

| Operator Training | Consider the training required for operators. | Affects compliance and overall productivity. |

| Budget | Establish your budget for purchasing or renting. | Shifts the scope of options available. |

| Future Projects | Consider if the crane will be used for future projects. | Could justify a more expensive, versatile model. |

Understanding Different Types of All Terrain Cranes Available

When selecting an all terrain crane, understanding different types is crucial. All terrain cranes combine mobility with lifting capacity. They have features that allow them to operate on various surfaces, from rough terrains to paved roads. According to industry reports, the global market for all terrain cranes is expected to grow by 7% annually through 2026. This growth indicates increased demand for versatile lifting equipment.

There are typically three main types of all terrain cranes. The first is the telescopic crane. It offers flexibility and ease of setup. These cranes can extend their booms to significant heights, making them suitable for urban construction projects.

The second type is the lattice boom crane. It is ideal for heavy lifting tasks. However, these cranes can be challenging to maneuver in tight spaces. The last type is the rough terrain crane, which excels in off-road conditions. These cranes might lack some lifting height compared to others, but they perform well on uneven ground.

Choosing the right type is not always straightforward. Each type has its unique benefits and limitations. For instance, a telescopic crane might not be the best choice for a very heavy load. Similarly, the rough terrain crane might struggle to lift loads at higher elevations. Analyzing project requirements carefully is essential for making an informed decision. Avoiding a one-size-fits-all approach can lead to mistakes that may affect productivity and safety.

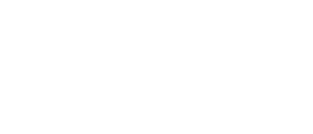

Key Specifications and Features for Your Project Needs

Choosing the right all-terrain crane for your project involves understanding key specifications and features critical for success. In 2026, the demand for versatile cranes will rise as projects become more complex. Factors such as lifting capacity, boom length, and mobility are essential. Research suggests that cranes with at least a 100-ton lifting capacity will be fundamental for medium to large-scale projects.

Tip: Analyze your specific project needs early. Lifting capacity must align with the heaviest loads. For example, if your project involves heavy steel structures or scaffolding, a crane with a higher capacity is crucial. Mobility also plays a significant role. A crane with a shorter turning radius will be more effective in tight spaces.

One must remember that not all all-terrain cranes are equal. Some models may lack versatility in different terrains. Project managers should consider ground conditions and choose a crane designed for diverse environments. Reports indicate that about 30% of crane failures arise from improper terrain management. Continually reflect on your site conditions and adjust your equipment choices accordingly.

Evaluating Lift Capacity and Reach for Optimal Performance

Selecting the right all-terrain crane is crucial for any project. Evaluating

lift capacity and reach

is essential for optimal performance. Each project has unique requirements, and understanding these factors can make all the difference.

Lift capacity refers to the weight a crane can safely lift.

It's critical to match this with your project's needs. If you underestimate, it can lead to accidents. Overestimating

wastes money. For instance, a crane that can lift 20 tons but only needs to lift

15 tons may incur unnecessary costs. Always check the maximum load limits.

Reach is about how far the crane can extend its arm.

It plays a vital role when maneuvering in tight spaces. If your site has obstacles, a crane with a longer reach may

be necessary. Keep in mind that every site is different. Consider space, terrain, and height. A crane with insufficient

reach may not complete your project on time.

Tip: Assess your site layout early. Understand where you need the crane most.

This can help you decide the appropriate reach.

Another tip: Don’t just check specifications. Speak with operators. Real-world

experience can highlight limitations often overlooked in data. Engage your team for insights on potential challenges.

Budgeting and Cost Analysis for All Terrain Crane Acquisition

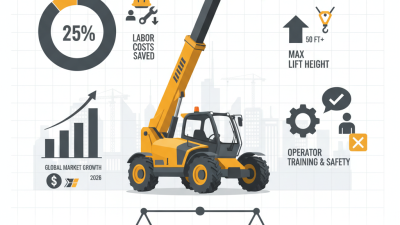

When acquiring an all-terrain crane, budgeting is critical. According to a 2023 industry report, operating costs can exceed $150,000 annually. This figure includes maintenance, fuel, and insurance. Buyers often overlook these recurring expenses. They focus solely on the initial purchase price.

Effective cost analysis requires understanding these hidden costs. For instance, maintenance can average around $10,000 to $30,000 yearly, depending on usage. Fuel efficiency also plays a role. Cranes with lower fuel consumption often have higher upfront costs but yield savings in the long run. Many firms fail to factor in these operational expenses, leading to budget overruns.

Before making a final decision, conducting a comprehensive cost-benefit analysis is essential. This analysis should include both direct and indirect costs. Selecting the right crane isn't just about the purchase price. It’s an investment that should provide value over time. Each project has unique needs. Balance initial costs with overall project goals to ensure sustainable growth and effective resource management.

Cost Analysis of All Terrain Cranes for 2026 Projects

Related Posts

-

10 Essential Tips for Operating Truck Cranes Safely and Efficiently

-

What is Crane Truck Rental and How Does it Work?

-

Why is a Telehandler Essential for Modern Construction Sites?

-

2025 Guide: How to Choose the Best Crane Truck Rental for Your Project

-

Top Reasons to Choose a Telehandler Lift for Your Construction Projects

-

2025 Top 5 City Crane Innovations Transforming Urban Construction