10 Essential Tips for Operating Truck Cranes Safely and Efficiently

In the ever-evolving landscape of heavy lifting and construction, the operational safety and efficiency of truck cranes have become paramount. According to industry reports, the average annual number of crane-related accidents in the U.S. stands at approximately 400, with a significant percentage attributed to operator error or inadequate safety measures. As demand for truck cranes in sectors like construction, infrastructure development, and logistics continues to rise, it is crucial to implement best practices that not only enhance performance but also prioritize worker safety.

The safe operation of truck cranes is vital not only to protect the well-being of the workforce but also to mitigate potential losses associated with accidents. The Bureau of Labor Statistics reports that crane accidents can lead to substantial economic costs, averaging up to $25,000 per incident when factoring in downtime and equipment repairs. By equipping operators with essential knowledge and adherence to safety protocols, stakeholders can significantly reduce these figures while improving productivity. This guide presents ten essential tips for operating truck cranes safely and efficiently, aimed at empowering operators and fostering a culture of safety in the workplace.

Understanding the Basics of Truck Crane Operation

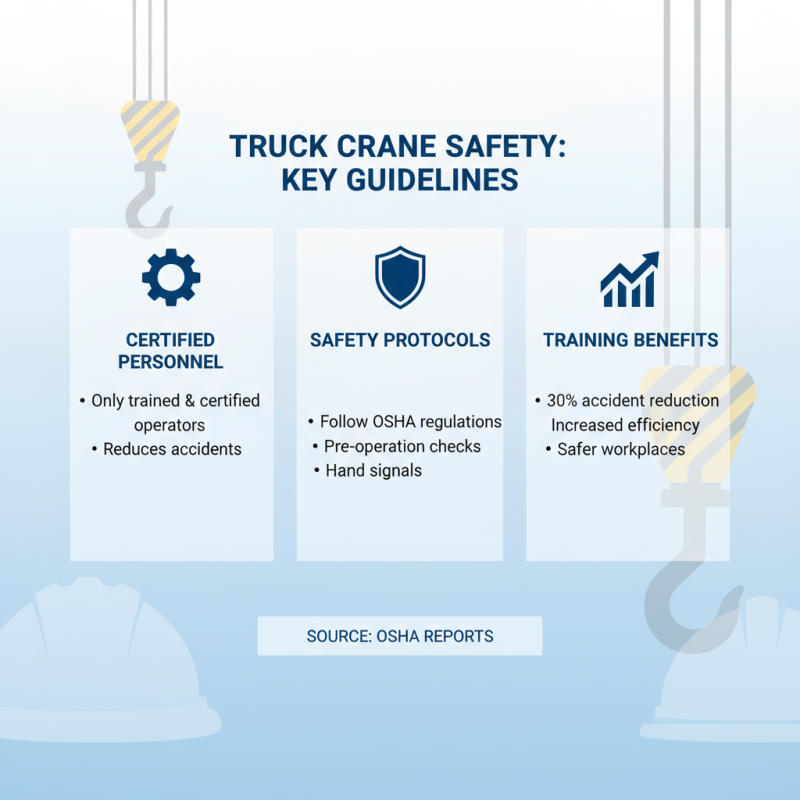

Operating truck cranes involves a foundational understanding of both equipment mechanics and safety protocols. According to the Occupational Safety and Health Administration (OSHA), improper crane operations account for approximately 20% of all construction-related fatalities. Therefore, knowing the basic principles of truck crane operation is crucial for mitigating risks on job sites. Proper training and awareness of the crane's load capacities, stability requirements, and operating procedures can significantly reduce the likelihood of accidents.

In addition to safety, efficient operation of truck cranes is vital for maximizing productivity. A study by the National Commission for the Certification of Crane Operators (NCCCO) revealed that trained operators complete tasks up to 30% faster than untrained personnel. This efficiency can be attributed to understanding the mechanics of the crane, including the impact of weight distribution, swing radius, and the importance of setup location. Ensuring that operators are well-versed in these principles allows for smoother operations and minimizes downtime, ultimately contributing to the overall success of construction projects.

Safety and Efficiency Metrics for Truck Crane Operation

Key Safety Regulations and Guidelines for Truck Cranes

Operating truck cranes safely and efficiently requires a comprehensive understanding of key safety regulations and guidelines. According to the Occupational Safety and Health Administration (OSHA), ensuring that only certified personnel operate cranes significantly mitigates the risk of accidents. OSHA states that improper use of crane equipment accounts for a substantial percentage of workplace fatalities, emphasizing the need for rigorous training and adherence to safety protocols. In fact, reports indicate that organizations that implement proper training programs can reduce accident rates by as much as 30%.

Furthermore, adhering to the American National Standards Institute (ANSI) guidelines is crucial for maintaining operational safety. These guidelines include regular inspections, maintenance checks, and the importance of using appropriate rigging techniques. Data shows that nearly 75% of crane-related incidents could be avoided with proper compliance to these standards. It is essential for operators to stay informed about current regulations and to participate in ongoing safety education, as this knowledge directly contributes to safe crane operations and enhances overall efficiency on job sites. Implementing these safety guidelines not only protects workers but also promotes better performance and reliability in truck crane operations.

Pre-Operation Checklist: Ensuring Safety Before Lifting

Before operating a truck crane, conducting a thorough pre-operation checklist is essential to ensure safety and efficiency. This checklist should include inspecting the crane's mechanical components, such as the hoist, boom, and outriggers. Operators should look for any signs of wear or damage and ensure all safety devices are functioning properly. Checking fluid levels, including oil and hydraulic fluid, is crucial to avoid operational failures during lifting tasks. Additionally, confirming the stability and levelness of the ground where the crane will be positioned can prevent tipping and accidents.

It is equally important to evaluate the lifting site and load conditions. Operators should assess overhead hazards, such as power lines or buildings, which could interfere with crane operation. Knowing the weight of the load is also critical; exceeding the crane's rated capacity can lead to catastrophic failures. Communication with the lifting crew is vital, ensuring everyone understands the plan and signals for operation. By dedicating time to this pre-operation checklist, operators can enhance safety and maintain a smooth workflow throughout their lifting operations.

Effective Techniques for Load Management and Stability

Effective load management is a critical aspect of operating truck cranes safely and efficiently. One of the key techniques involves assessing the load's weight and dimensions before attempting any lift. Operators should utilize load charts to determine the crane's capacity and ensure that it is not exceeded. Additionally, it is essential to maintain proper load distribution, as uneven weight can lead to instability. Employing the right rigging equipment and techniques helps to secure the load properly, preventing any shifting during lifting, which can jeopardize safety and efficient operations.

Stability is paramount when operating truck cranes, especially in challenging environments. Operators must always consider the ground conditions and ensure that the crane is set up on a stable and level surface. Utilizing outriggers or stabilizers can significantly enhance the crane's stability during operations. Furthermore, vigilance throughout the load lift process is crucial; operators should continuously monitor the load's position and the crane's movement. By maintaining clear communication with the ground crew and using hand signals or radios, potential hazards can be managed effectively, ensuring a secure and efficient lifting process.

Post-Operation Procedures: Best Practices for Safety and Maintenance

Post-operation procedures are critical for ensuring the safety and longevity of truck cranes. After completing lifting tasks, operators should conduct a thorough inspection of the crane. This involves checking for any visible signs of wear and damage on key components such as ropes, hooks, and stabilizers. Operators should also examine fluid levels and look for leaks in the hydraulic system, as these can lead to larger issues if left unaddressed. Documenting these observations in a maintenance log not only helps track the crane's condition over time but also fosters an environment of accountability and safety.

In addition to physical inspections, proper cleaning and storage of the crane are essential elements of post-operation practices. Cranes should be cleaned to remove dirt, debris, and corrosive materials that can affect their performance. Moreover, it is important to store the crane securely in a designated area, away from potential hazards or weather elements that could lead to deterioration. Ensuring that all safety features are functional before the next operation encourages a culture of preventive maintenance, ultimately minimizing the risk of accidents and optimizing efficiency in future lifting tasks.

Related Posts

-

10 Best Types of Construction Cranes for Efficient Project Management

-

2025 Top 10 Self Erecting Crane Models Revolutionizing Construction Efficiency

-

2025 How to Choose the Best City Crane for Your Construction Needs

-

2025 Guide: How to Choose the Best Crane Truck Rental for Your Project

-

2025 Top 5 City Crane Innovations Transforming Urban Construction

-

Top 5 Boom Trucks That Will Transform Your Construction Projects